Contexte du Projet

RealDev a été choisi comme partenaire par Avery Dennison pour jouer un rôle essentiel dans l'expansion de leurs opérations. Notre bureau d'étude et réalisation a mis son expertise au service de ce projet, en gérant toutes les étapes, de l'étude à la mise en service de la nouvelle installation.

Notre équipe chez RealDev est spécialisée dans divers domaines techniques, tels que l'électricité, l'automatisation, le contrôle-commande, la régulation, l'instrumentation, ainsi que la gestion des alarmes et des interlocks. Nous avons délivré une solution complète et fiable qui répondent aux exigences spécifiques du client.

Dans le cadre de ce projet d'expansion, nous avons travaillé en étroite collaboration avec le client pour atteindre les objectifs fonctionnels suivants :

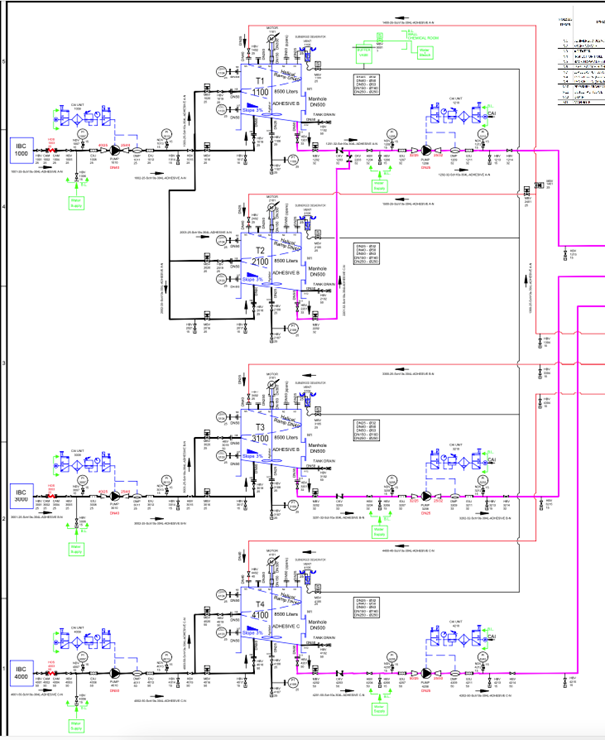

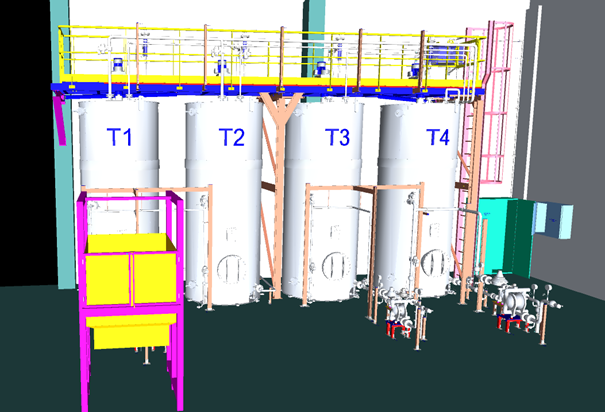

Gestion des transferts IBC (Intermediate Bulk Containers) vers les cuves : Notre équipe a mis en place un système efficace permettant un transfert fluide et sécurisé des matières premières des IBC (Intermediate Bulk Containers) vers les cuves, en tenant compte des besoins précis du client

Gestion des nouveaux agitateurs dans les cuves : Nous avons intégré des agitateurs de pointe dans les cuves, offrant une solution sur mesure pour un mélange optimal des substances, assurant ainsi une qualité constante des produits.

Gestion du transfert des cuves vers un trolley : RealDev a développé une solution intelligente facilitant le déplacement et la manipulation des matières premières en transférant les cuves vers un trolley, répondant ainsi aux spécifications particulières du client.

Mission de RealDev

Notre mission chez RealDev comprend les étapes suivantes, toutes réalisées avec succès :

Analyse fonctionnelle détaillée : Nous avons effectué une étude approfondie des besoins spécifiques du client pour concevoir une solution sur mesure répondant à leurs attentes précises.

Création de la documentation : Notre équipe a préparé une documentation complète et claire, incluant les schémas électriques, les plans d'automatisation et les spécifications techniques, afin de faciliter la compréhension et la gestion future optimale de l'installation.

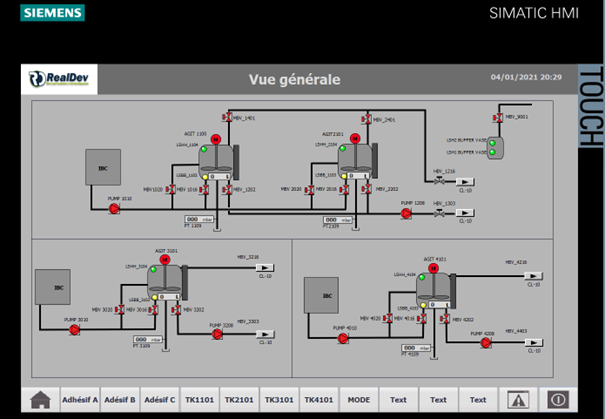

Développement des codes PLC et HMI : Notre équipe a personnalisé les codes PLC et HMI pour répondre aux besoins spécifiques, garantissant ainsi des performances optimales et une gestion efficace de l'installation.

Réalisation des tests en usine (FAT) : Nous avons procédé à des tests approfondis en usine pour valider la conformité et la fiabilité de notre solution avant son déploiement sur site.

Installation et mise en service : Nos experts ont supervisé l'installation complète du système chez le client, assurant une mise en service et une transition fluide.

Tests d'acceptation sur site (SAT) et qualification : Nous avons effectué des tests approfondis pour vérifier que toutes les composantes du projet fonctionnent correctement et répondent aux spécifications initiales.

Remise du projet (Handover) : Une fois le projet terminé et validé, nous avons officiellement remis l'installation au client, en fournissant une formation adéquate pour une utilisation optimale du système.

Chez RealDev, nous sommes fiers de notre partenariat avec Avery Dennison et de notre expertise en matière d'industrie 4.0. Notre équipe hautement qualifiée et notre engagement envers l'excellence nous permettent de relever les défis les plus exigeants et de fournir des solutions innovantes à nos clients.