Résultats :

Intégration réussie des automates dans la chaîne, conforme aux normes strictes de sécurité et d’hygiène.

Contexte du Projet

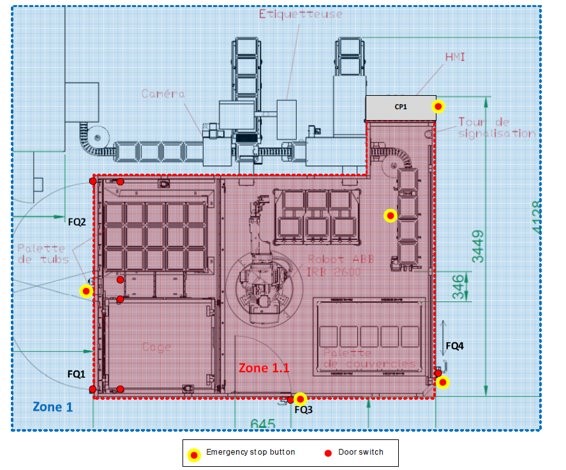

Un de nos clients, spécialisé dans le secteur des sciences de la vie, a commandé plusieurs robots qu'il souhaitait intégrer dans sa chaîne de packaging. Le rôle de ces robots est la palettisation et dépalettisation de boites de vaccins. Étant donné que ce secteur industriel est soumis à des normes de sécurité et d'hygiène très strictes, une telle opération nécessite parfois l'intervention d'un bureau d'études. C'est là que RealDev entre en jeu.

Mission de RealDev

Dans ce projet, trois acteurs majeurs ont été impliqués :

- Le fournisseur des robots ;

- Le client qui a du définir son besoin fonctionnel ;

- RealDev, qui a joué un rôle essentiel en tant que chef d’orchestre.

Dans l'ordre, les responsabilités de RealDev étaient les suivantes :

1. Analyser l'ensemble des documents relatifs aux robots fournis par le fournisseur ;

2.

Identifier les éléments à modifier dans cette documentation technique, signaler les points à améliorer et suivre leur mise en œuvre ;

3. Avant la livraison des robots chez notre client, notre équipe s'est rendue chez le fournisseur pour effectuer des tests approfondis afin de vérifier leur bon fonctionnement ;

4.

Nous nous sommes rendus chez notre client pour vérifier la disponibilité des emplacements d'installation des robots, ainsi que la présence de prises réseau et d'alimentation adéquates ;

5. Nous avons apporté notre aide lors de la livraison et de la réception des robots chez le client ;

6. Nous avons assisté à l'installation des robots aux emplacements appropriés ;

7. Nous avons préparé des protocoles et effectué des vérifications de fonctionnement des machines ;

8. Enfin, nous avons contribué à la mise en production des automates.

RealDev a été choisi pour effectuer des contrôles, des vérifications et la gestion des équipes dans ce projet. Notre réputation repose sur la livraison de résultats de haute qualité, accordant une grande importance aux détails. Grâce à notre expertise, nous avons supervisé l'intégration des automates dans la chaîne de production de notre client, en respectant les normes de sécurité et d'hygiène strictes du secteur des sciences de la vie.

Faite confiance à RealDev garantit une expertise, un suivi méticuleux et des résultats exceptionnels dans vos projets.